Home \ Solutions \ Direct Mail & Post Press \ Paper Wrapping

Cutting edge in-line paper wrapping systems for high-volume mailers and printers. We offer a range of different paper wrap options.

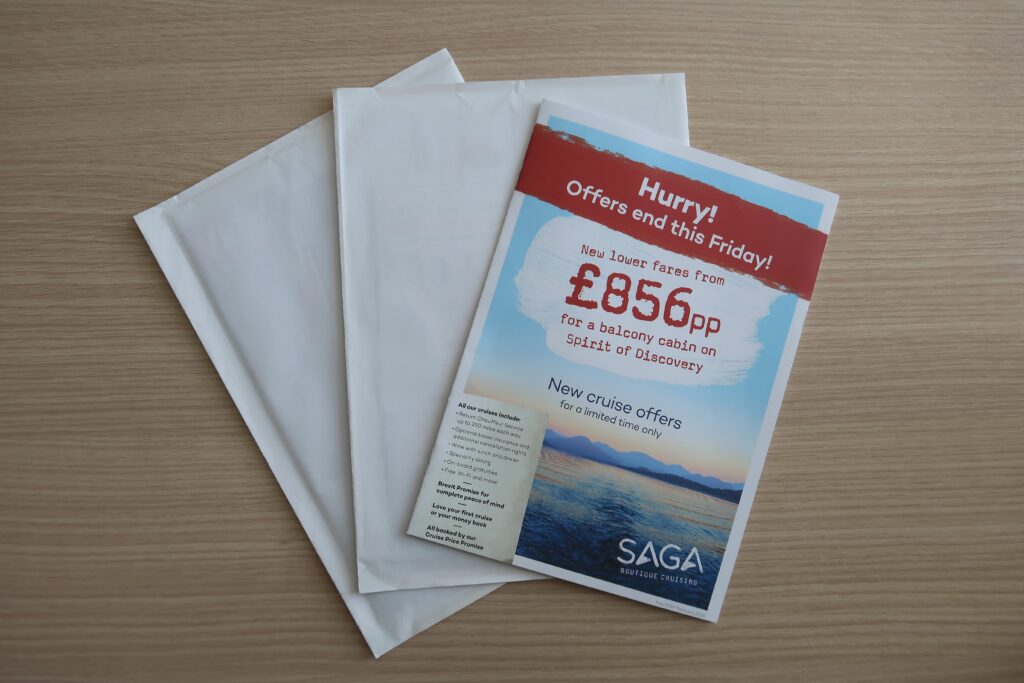

When it comes to Direct Marketing, nothing is more important than the communications impact and Paper Wrapping provides not only the ability to send high impact messages it provides opportunities for valuable personalisation.

There are a number of alternative Paper Wrapping options available and these can be supplied new, and in some cases existing equipment can be converted. Our engineers are also able to modify some existing Sitma Polywrapping machines to handle both paper and poly wrapping requirements.

Our partners

Stay ahead with paper wrap solutions that wrap documents in paper

The system provides high performances in 24/7 production environments and creates envelopes from C6/5 up to C4.

This wrapping system can be easily configured to accept variable printing applications, camera systems, and external PC-Controllers.

Main Features include:

- Produces both transactional and direct mail-pieces

- Wraps letters and inserts on-the-fly increasing productivity

- Uses rolls of white paper to replace traditional envelopes

- Reduces mail-piece costs by 20% to 40% by reducing labour requirements

- Outputs more than 50,000 envelopes in 2 hours

- Produces closed-face envelopes with scalloped flap or windowed envelopes

- Generates on-demand logos, graphics and messages on the fly

- Possibility of high quality Color Inkjet System to print variable, full color text and images

- Eliminates preprinted envelopes and storage needs

- Makes envelopes more effective with bright color graphics

- Uses quick drying inks without a dryer

- Improves operational efficiency

- Utilizes both inside and outside of the mail-piece

- able to combine and presort mixed jobs prior to printing, eliminating job changeover

Contact us