Injection Moulder designed to reliably test and evaluate new or expensive materials and formulations.

Xplore micro injection moulders let you test and evaluate new or high-value materials and formulations with exceptional reliability and reproducibility. They deliver fast, cost-effective results using only very small amounts of material.

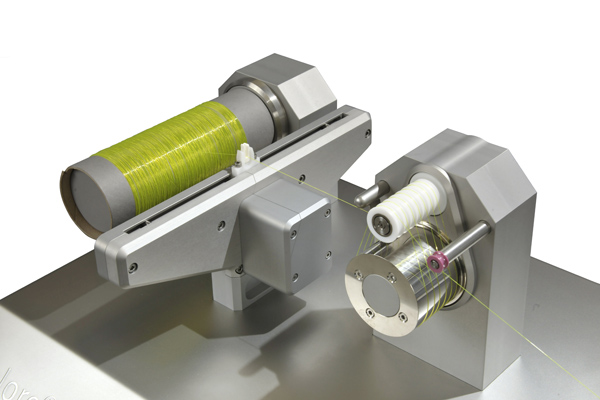

At the core of each laboratory micro injection moulder is a temperature-controlled mould housing that holds a conically shaped mould, paired with a heated, removable injection nozzle unit. The divisible conical mould fits securely into the housing, preventing opening during injection and eliminating flashing.

With shot volumes of 5.5 or 12 ml, these compact micro injection moulders fit easily on a laboratory bench or inside a hood. The IM 5.5 and IM 12 integrate seamlessly with Xplore twin-screw compounders, helping you streamline R&D screening from compounding to moulding.

The ideal injection moulder for rapid material screening and development in research environments.

The injection unit fills directly from an Xplore Micro Compounder, enabling one or two injection cycles per batch depending on the sample volume. Standard mould options cover tensile and impact bars, plaques, and custom shapes tailored to your design requirements.

This video demonstrates how easily you can produce a test piece using the Micro Compounder.