Home \ Manufacturers

Automation and robotics for efficient, sustainable logistics

View our range

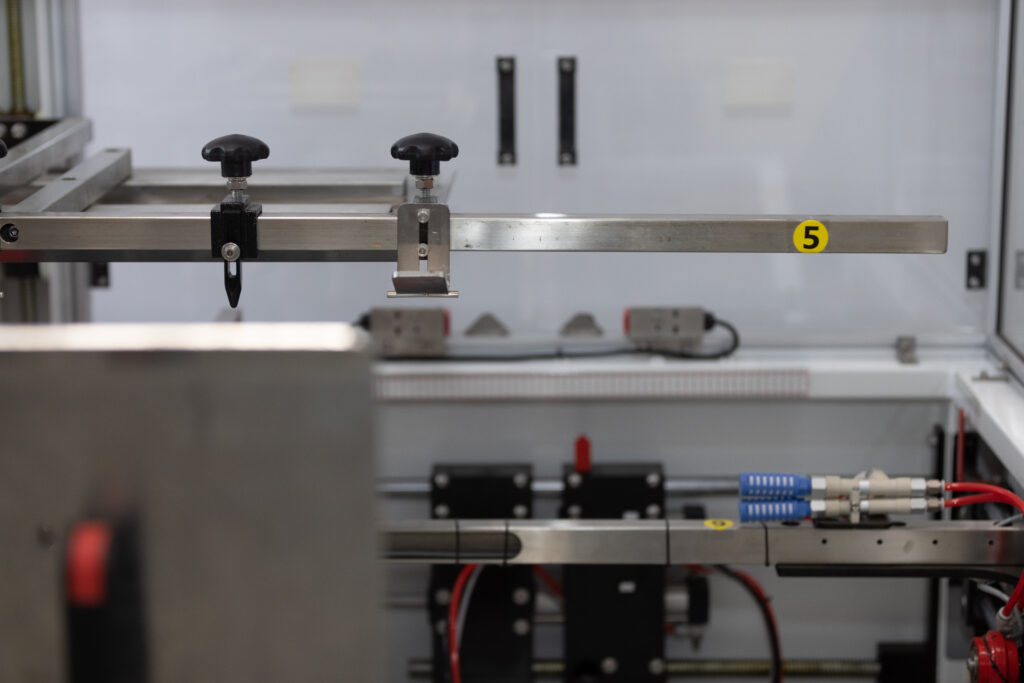

Innovative and dependable packaging machine solutions

View our range

Transform raw materials into finished products with precision and efficiency

View our range

Fast delivery of inks and machine spares

View our range

Robust, reliable machines at the heart of direct mail and post press production

View our range

Processing machines for manufacturing consistent, high-quality food product

View our range

Rubber and plastics testing for material development and quality control

View our range

Paper and plastic reels, pouches and doypacks, tubs and containers

View our range

Address

Engelmann & Buckham Ltd

Weybourne House

Lenten Street, Alton

Hampshire, GU34 1HH