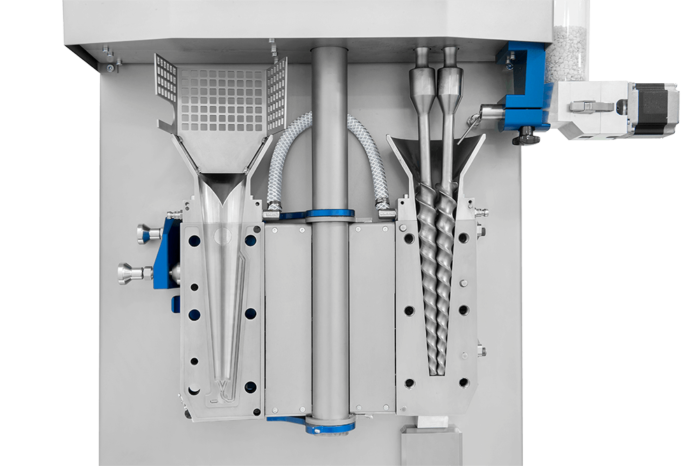

The Xplore MC40, is a 40ml lab micro compounder for plastic testing

It is an essential piece of equipment for every R&D and quality control lab that is working with larger amounts of plastics, resins, compounds, elastomers, or film, filament and reactive extrusion. It can handle larger 40ml batch sizes.

● rpm range (1-500), higher shear rates hence excellent dispersion, easier to scale up

● screw torque (40 Nm) within the 1-500 rpm range, more stable extrusion rate

● longer residence time in continuous mode compounding

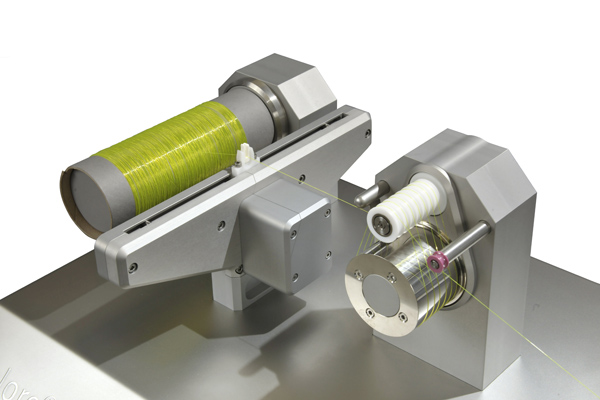

● excellent control over throughput, improved dimensional stability of spun filaments and casted films

● strong accurate 24 bits motor drive, so mixing of higher viscous compounds now possible

● small foot print, lower housing, so easier to move and install in a fume cupboard

● stiffer housing, so less wear of screws and barrel, longer life time, less maintenance

● by design easier to work with, to install add-ons (film or fibre line) and to maintain

● maximum operating temperature 450 C

Melt torque: 40 Nm within the 1 – 500 rpm range! Download the brochure here:

A screw torque of 40 Nm makes processing rubbers and elastomers effortless

Important options include Xplore’s proprietary rheological software, which enables up-scaling to large parallel twin screw extruders. The MC40 looks similar to the MC15 HT, but is better for when a larger yield is desired for subsequent analysing steps, it gives unique application possibilities where amount of processed material is key.

This design delivers significantly more thorough mixing compared to the commonly used tangential screw mixers. Every cubic centimeter of material exhibits identical properties, ensuring unparalleled consistency. In contrast, tangential screw designs often struggle to produce uniform samples, making consistency a persistent challenge.