A range of drum filling machines for IBCs, containers and drums

We offer automatic and semi automatic filling machinery including our pallet conveyor line for filling drums, containers and pails.

Features:

- Semi automatic drum filling machine for 25 to 1500 kg capacity containers on a pallet.

- Automatic weight filling.

- Automatic pallet feed and evacuation thanks to roller or chain conveyors.

- For medium production outputs or frequent product and container type changes.

- Interchangeable filling lance.

- The machine can control a conveyor line.

- Available in ATEX version and immersion filling.

- Electro-pneumatic controls.

Automatic drum filling, barrel and container filling machine

A fully automatic weight filling machine, for drums, barrels and containers ranging from 50 to 250 litres (compatible with plastic and metallic drums). The machine features two workstations: one which performs bunghole location and uncapping (optional feature) and the weight filling workstation.

Benefits:

- Automatic container feeding and evacuation.

- For large productions, with a medium-high automation rate.

- Container format may be changed easily and without need for tools.

- Interchangeable filling valve.

- Available in ATEX version.

- Below-surface filling option available.

- Electro-pneumatic controls.

- Allows full control over a conveyor line.

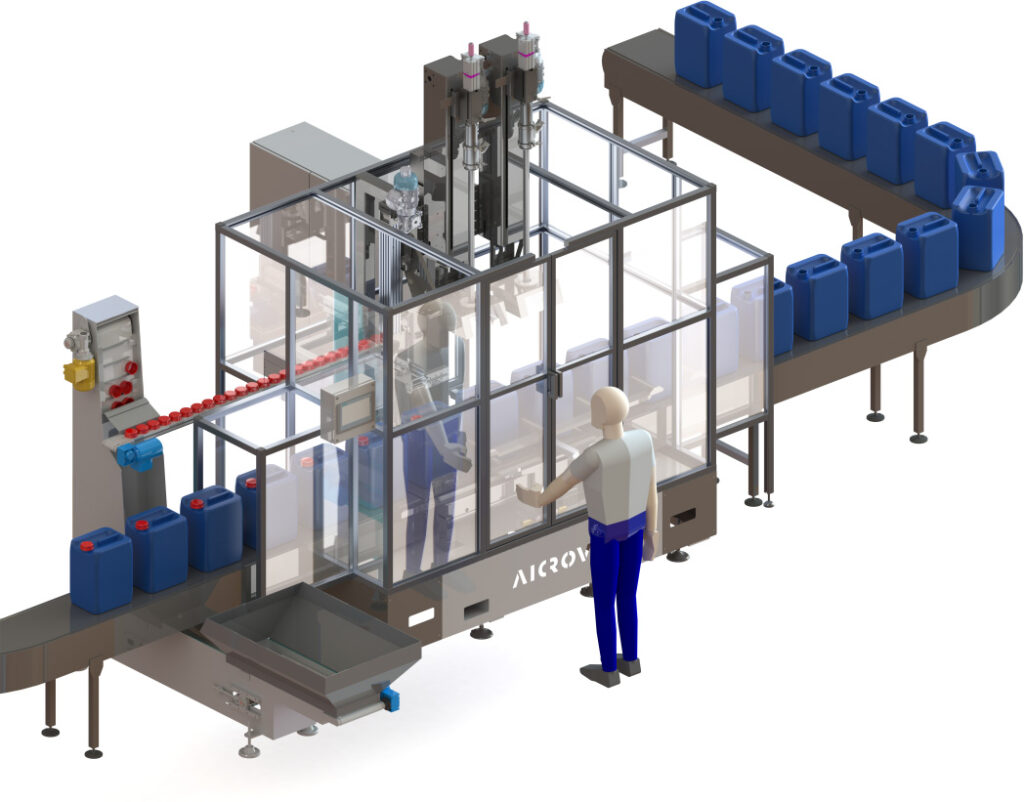

Robot Filler for IBCs, drums and canisters

This automatic liquid filling machine is designed for filling IBCs, totes, drums, barrels and canisters. Functions include:

- Automatic uncapping and capping station

- A sealing station featuring a sealing head for plastic pressure seals.

- Designed for high-volume production environments

- Highly automated and flexible for handling different container size and types and sizes

- It can fill containers ranging from 20 to 1,500 litres, directly on pallets

- Suitable for both liquid and viscous products

These are just examples of what we can offer. We have a wide range of equipment for all different industries. Please contact us about other options