Home \ Solutions \ Processing \ Scraped Surface Heat Exchanger

Equipment for the heating and cooling of high-viscous products

The Rono scraped surface heat exchanger offers cutting-edge technology that optimizes heating and cooling for high-viscous products such as:

- table margarine, low fat spreads

- bakery margarine, puff pastry margarine

- butter, butter products

- shortening, bakery fats

- fat-sugar mixtures, biscuit cream, wafer fillings

This innovative equipment employs a rotating scraper that continuously removes product buildup on the heat transfer surface, ensuring maximum heat exchange and minimizing fouling.

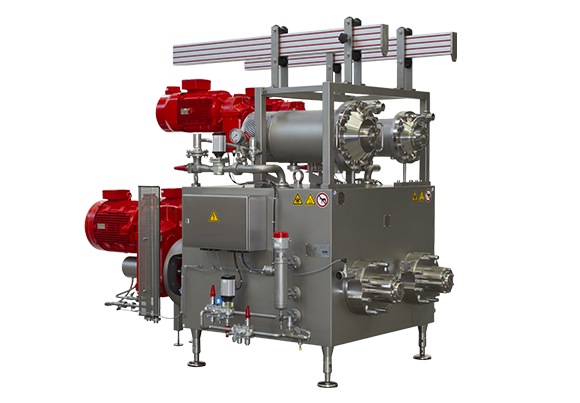

With its compact design and advanced features, the Rono scraped surface heat exchanger offers precise temperature control, high thermal efficiency, and easy maintenance, making it a reliable and efficient solution for heat transfer requirements.

Our partners

Used for the pasteurisation and crystallisation of spreads such as margarine, shortening or other edible fats

The scraped surface heat exchanger is state of the art, it is continually developed and improved based on the operational experience of well-known producers.

Customers requirements for the final product are considered and the temperature and capacity determines the necessary heat exchange surface.

The RONOTHOR is modular and very flexible, with up to six heating or cooling units mounted within a common frame. Each unit is equipped with an independent refrigeration system and variable gear.

Contact us